How Are Plastic Bags Made

Today garbage bags are created in large plants using heavy machinery. If you care about the environment and want to learn how biodegradable plastic decomposes the outline below should provide you with the essential information.

How Are Plastic Shopping Bags Made Bright Hub Engineering

How Are Plastic Shopping Bags Made Bright Hub Engineering

For plastic bags its more common to.

How are plastic bags made. What happens to the plastic bags. They are most often made from Polyethylene that takes centuries to degrade. Chapter Two How are Plastic Bags Made.

The first step to making plastic bags is to extract the raw material. Plastic bags can be made from biodegradable plastics that break down much faster than traditional plastic bags. Step 1 Extraction of crude oil and natural gas.

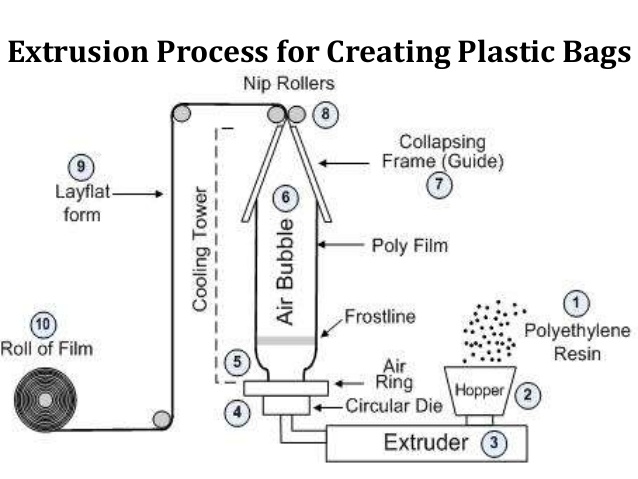

The air is then pumped down from below to create a very thin balloon of flexible plastic. First polyethylene beads or resin are loaded into a hopper which deposits resin into the barrel which also contains a screw. A company must have special equipment to create the bag however there are just two steps required to make the bags.

As the screw motor turns the screw the resin is. The raw material polyethylene can be sourced from either refined oil or cracked gas what is cracked gas. Polyethylene the most common type of plastic used for disposable bags was first created in 1898 but it was not until the mid 1950s that a high-density polyethylene was invented.

Both are very easy to create but the plastic bag is far easier to create than a book. Plastic bags are made of Polyethylene that is either low density or high density Polyethylene or sometimes a combination of both. A process called extrusion is the first step in making a plastic bag.

How are plastic bags made. The polyethylene that makes plastic bags is derived either from refined oil or cracked natural gas. These plastic bags or polybags begin as ethane molecules a byproduct of natural gas production which are heated at 1500 degrees Fahrenheit at a cracker plant so-called because the intense heat forces the molecules to crack and form new substances including ethylene gas.

It takes up to 1000 years for a plastic bag to break down. Plastic Bag Manufacturing Starts with Raw Material Extraction. Production begins by re-heating the pallets to very high temperatures and compressing them to turn them into liquid.

This process disrupts the local ecosystem and can present disastrous consequences for human and environmental health if leaks occur. Working with molten plastic can be surprisingly delicate and beautiful. Some plastics come from polymers.

The production of plastic bags begins with a polymer. High density polyethylene was the breakthrough that enabled the production of cheap yet strong plastic bags. Ethylene is derived from natural gas and petroleum.

To create a plastic bag the process is similar to the process for creating a book. Heres a simple explanation of the process. Manufacture and composition Traditional plastic bags are usually made from polyethylene which consists of long chains of ethylene monomers.

12 minutes of use 1000 years of pollution. Ad Buy Direct and Save. On average a plastic shopping bag is used for just 12 minutes.

The first step of making plastic bags is to extract the raw material. Lets take a closer look at how plastic bags are made as well as a cost-effective alternative to using virgin resins in plastic bag manufacturing. Plastic bags are manufactured using extrusion which pushes melted plastic into a die that determines the final thickness of the bag.

Each ton of recycled plastic bags saves the energy equivalent of 11 barrels of oil. An extruder is used to heat the. The process used to manufacture plastic shopping bags is called blown film extrusion.

This plastic balloon is then further stretched by special machines to. This molecule houses units called monomers that bond together to form a basis for plastic. Polyethylene is a constituent of petroleum products crude oil and natural gas and is separated through the process of fractional distillation.

Ad Buy Direct and Save. These hydrocarbons are found mostly underground and must therefore be reached by drilling wells. They are created in long tubes then cut and separated to produce individual bags.

Die Cut Punch Out Handle Bags Description About Cheapest On Alibaba Die Cut Plastic Bag Multiple Colors With Handle Made By A C Plastics Joint Stock Company On China Suppliers Mobile 114245433

Die Cut Punch Out Handle Bags Description About Cheapest On Alibaba Die Cut Plastic Bag Multiple Colors With Handle Made By A C Plastics Joint Stock Company On China Suppliers Mobile 114245433

How Plastic Bags Are Made In 10 Steps

How Plastic Bags Are Made In 10 Steps

The Handbag Made From Plastic Bags Circularthreadz

The Handbag Made From Plastic Bags Circularthreadz

How Are Plastic Bags Made Xl Plastics

How Are Plastic Bags Made Xl Plastics

How It S Made Plastic Bags Youtube

How It S Made Plastic Bags Youtube

Plastic Bag Ban Washington State Department Of Ecology

Plastic Bag Ban Washington State Department Of Ecology

What Are Plastic Bags Made Out Of Feature Chicago Reader

What Are Plastic Bags Made Out Of Feature Chicago Reader

How Are Plastic Bags Made The Step By Step Process

How Are Plastic Bags Made The Step By Step Process

The Fate Of Plastic Bags German Economic Institute

The Fate Of Plastic Bags German Economic Institute

How Plastic Bags Are Made Step By Step Environment Buddy

How Plastic Bags Are Made Step By Step Environment Buddy

I Am A Plastic Bag Is Made From Recycled Single Use Plastic Bottles

I Am A Plastic Bag Is Made From Recycled Single Use Plastic Bottles

A Cleaner Tomorrow Diy Projects Made From Plastic Bags Plastic Bags Diy Plastic Bag Crafts Recycled Plastic Bags

A Cleaner Tomorrow Diy Projects Made From Plastic Bags Plastic Bags Diy Plastic Bag Crafts Recycled Plastic Bags

Plastic Bag Recycled Content Goal Crafting A Green World

Plastic Bag Recycled Content Goal Crafting A Green World

Comments

Post a Comment